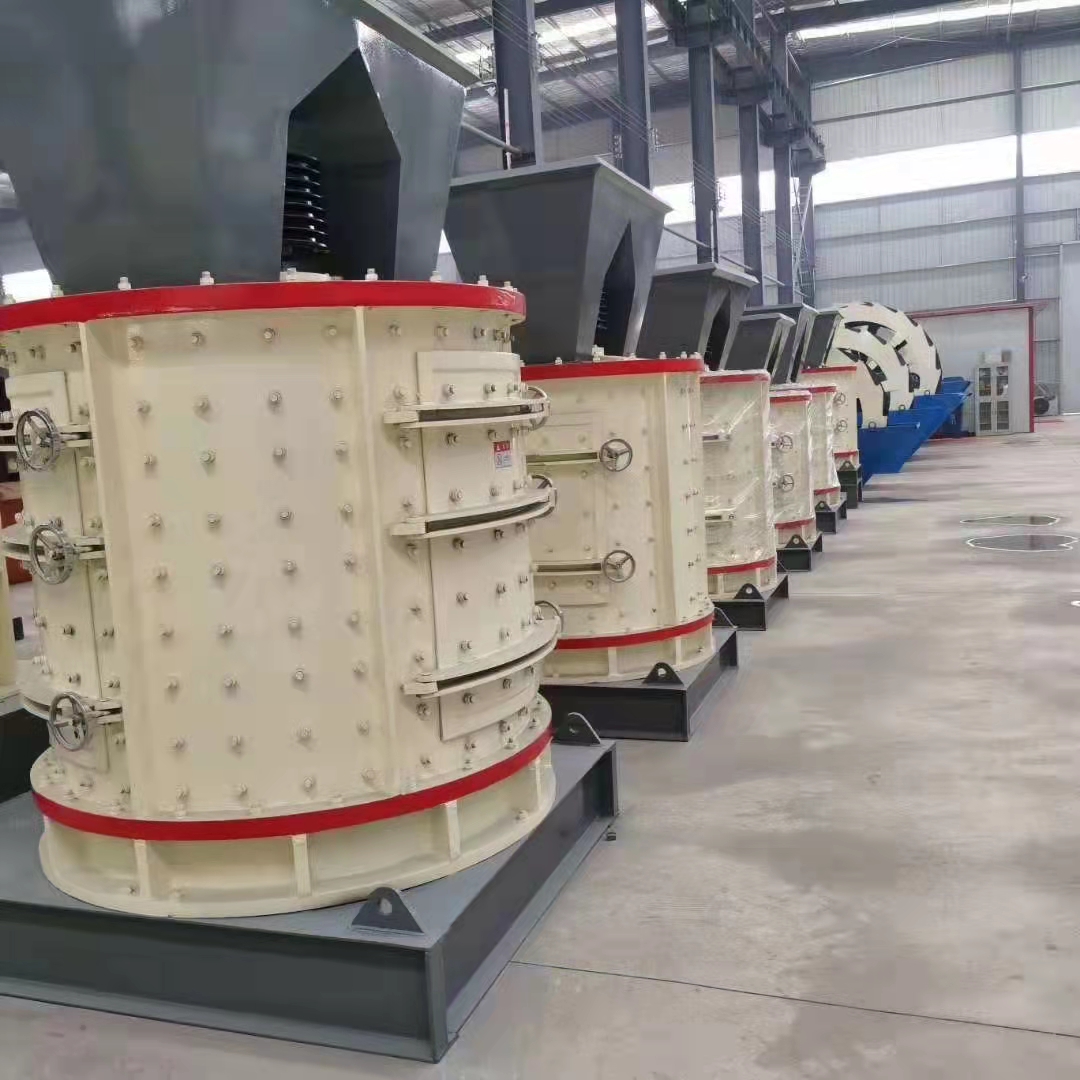

Vertical shaft sand making machine

throughput : 20-200t/h

application area : <100mm

Applicable materials : Pebbles, construction waste, river pebbles, quartz sand, granite, basalt, iron ore, limestone, quartzite, etc

CMC

CPA

CNEX

ISO

Vertical shaft sand making machine, referred to as vertical shaft crusher, is a new product optimized and designed by Keguan company in combination with fine crushing technology at home and abroad. Its performance has reached the domestic advanced level. It can be widely used in mining, metallurgy, refractory, cement, coal, glass, ceramics, electric power and other industries. The heavy vertical shaft sand making machine has the characteristics of large crushing ratio, freely adjustable discharge particle size, no influence of plate hammer and liner wear, no screen bar setting, and materials with high moisture content and large mud content should not be blocked.

Working principle

The lump ore falls into the upper throwing plate in the upper crushing cavity by the feeding hopper. With the help of the centrifugal force of the throwing plate, the material is thrown to the inner wall of the cylinder, which collides violently with the impact plate installed on the inner wall. At the same time, the materials collide with each other, making them break or produce a large number of hairline cracks. After entering the conical rotor cavity, the materials fall in a spiral shape in the conical space, and the cracks are formed by pressing and pressing The ore is further broken. Because of the slope between the cone-shaped rotor and the liner, the smaller materials move downward and realize the grading crushing automatically from large to small. The material is hit by the hammer in the cone-shaped rotor cavity, and the high-speed running block material collides with the impact plate again and the material flow collides with each other, so that the material is crushed by the impact, impact, shear and extrusion surface, so as to improve the crushing efficiency.

Advantage

1. The crushing ratio of heavy vertical shaft crusher is large, and there is no screen bar setting, and the material with high moisture content and large mud content will not be blocked.

2. The bearing is arranged horizontally with long service life and can crush materials with high temperature (such as cement clinker).

3. Elastic adjusting mechanism is adopted to automatically discharge the non broken materials, which will not cause damage to the equipment.

4. The structure of the rotor body of the machine is unique, and the rotor body is hardly worn when crushing materials. Moreover, the back cavity is equipped with screw rod or hydraulic opening mechanism, so the vulnerable parts can be easily replaced without starting the main equipment.

5. The wearing parts are made of high hardness, high toughness and multi-element alloy wear-resistant material, and the service life is increased by 2-3 times; the gap between hammer head and impact plate is adjustable, which can meet the crushing requirements of various materials.

Specifications

Model | Feeding Size(mm) | Output Size(mm) | Capacity (t/h) | Power(kw) | Overall Dimension (L*W*H) |

PFL-800 | < 50 | < 3-5 | 10-20 | 22-37 | 2100*1200*1700 |

PFL-1000 | < 80 | 20-40 | 45-75 | 2600*1400*1900 | |

PFL-1250 | < 150 | 40-70 | 75-132 | 2800*1600*2100 | |

PFL-1500 | < 180 | 70-100 | 132-200 | 3100*1900*2200 | |

PFL-1750 | < 200 | 130-190 | 200-315 | 3710*2360*2390 | |

PFL-2000 | < 220 | 200-260 | 315-355 | 4100*2660*2620 |