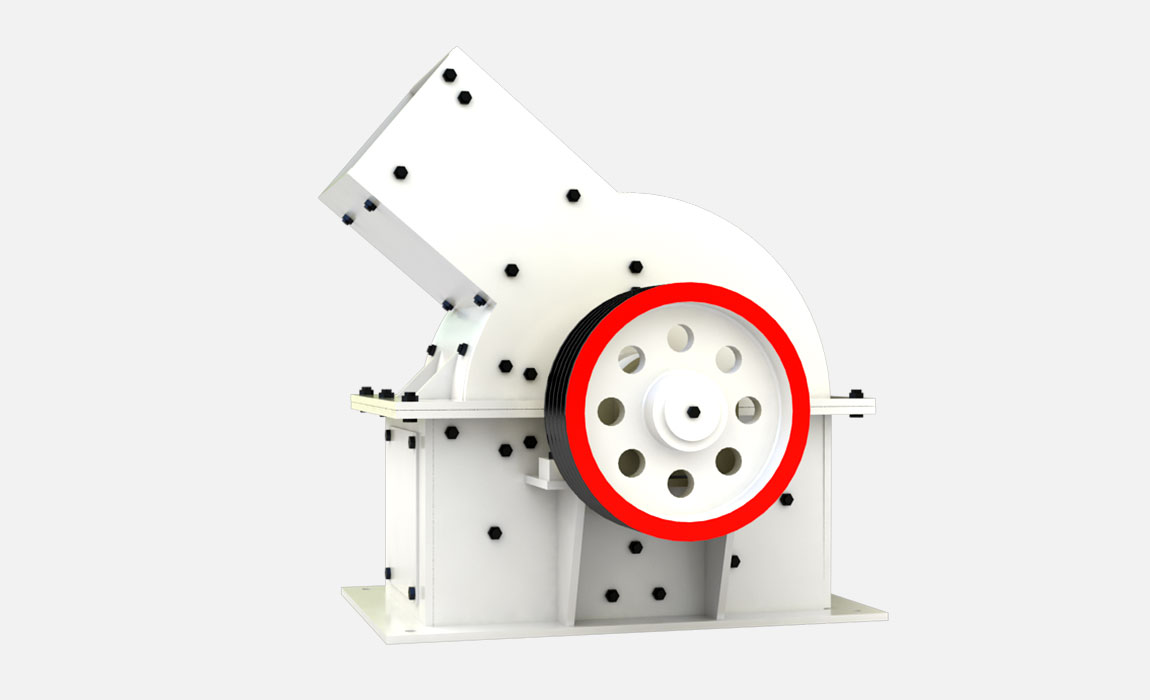

PC hammer crusher

throughput : 5-80t/h

application area : ≤500mm

Applicable materials : Hammer crusher is mainly used for crushing medium hardness and brittle materials, such as coal, cement, gypsum, alum, brick, tile, limestone, etc

CMC

CPA

CNEX

ISO

This product is broken by the high-speed rotating hammer and material collision surface. It has the characteristics of simple structure, large crushing ratio and high production efficiency. It can be broken in two forms of dry and wet. It is suitable for crushing medium hardness and brittle materials in mining, cement, coal, metallurgy, building materials, highway, combustion and other departments. The equipment can adjust the gap between the castor bars and change the discharge particle size according to the user's requirements, so as to meet the different needs of different users.

Working principle

The main working part of hammer crusher is the rotor with hammer head, which is composed of main shaft, disc, pin shaft and hammer head. A sieve plate is arranged at the lower part of the rotor. The motor drives the rotor to rotate at a high speed in the crushing chamber, and the material enters the machine from the upper feeding port, and is crushed by the impact and grinding of the high-speed moving hammer head. The fine material smaller than the mesh size is discharged through the sieve plate, and the coarse material larger than the mesh size is prevented from further crushing on the sieve plate, and finally discharged through the sieve plate.

Advantage

The overall design is beautiful in appearance, and the structure seal is broken by hammering, which solves the dust pollution and ash leakage of the crushing workshop. According to the requirements of customers, the required granularity can be adjusted. Working hammer head, cast by new technology, has less wearing parts and convenient maintenance. It is an upgraded product.

Specifications

model | Feed size (mm) | Discharge particle size (mm) | Production capacity (T / h) | Power (kw) | Weight (T) | External dimension (mm) |

PCФ400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900 × 670 × 860 |

PCФ600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200 × 1050 × 1200 |

PCФ800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310 × 1180 × 1310 |

PCФ1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600 × 1390 × 1575 |

PCФ1000×1000 | ≤500 | ≤35 | 30-80 | 90 | 8 | 1800 × 1590 × 1775 |